SICK Inductive Proximity Sensor IMG18-08BNOZC0K | 1135599

- Diameter : Ø 18mm

- Sensing Range Sn : 8mm

- Switching Output : NPN/NC

- Installation Type : Flush

Description

SICK Inductive Proximity Sensor IMG18-08BNOZC0K | 1135599

Inductive Proximity Sensor Part No: 1135599

Inductive standard sensors for economical use in industrial environments

SICK’s inductive sensors offer precise detection, less downtime and a long service life. The inductive IME sensors pack high technology into the smallest of spaces. The integrated ASIC chip enables digital adjustment after the end of the manufacturing process. The saving of values in the ASIC ensures highly precise switching points and very high repeatability of values – for any number of production runs. IM sensors are completely encapsulated with hotmelt molding, which greatly increases shock and vibration resistance. The customer benefits from high positioning accuracy in the machine and long-term reliability.

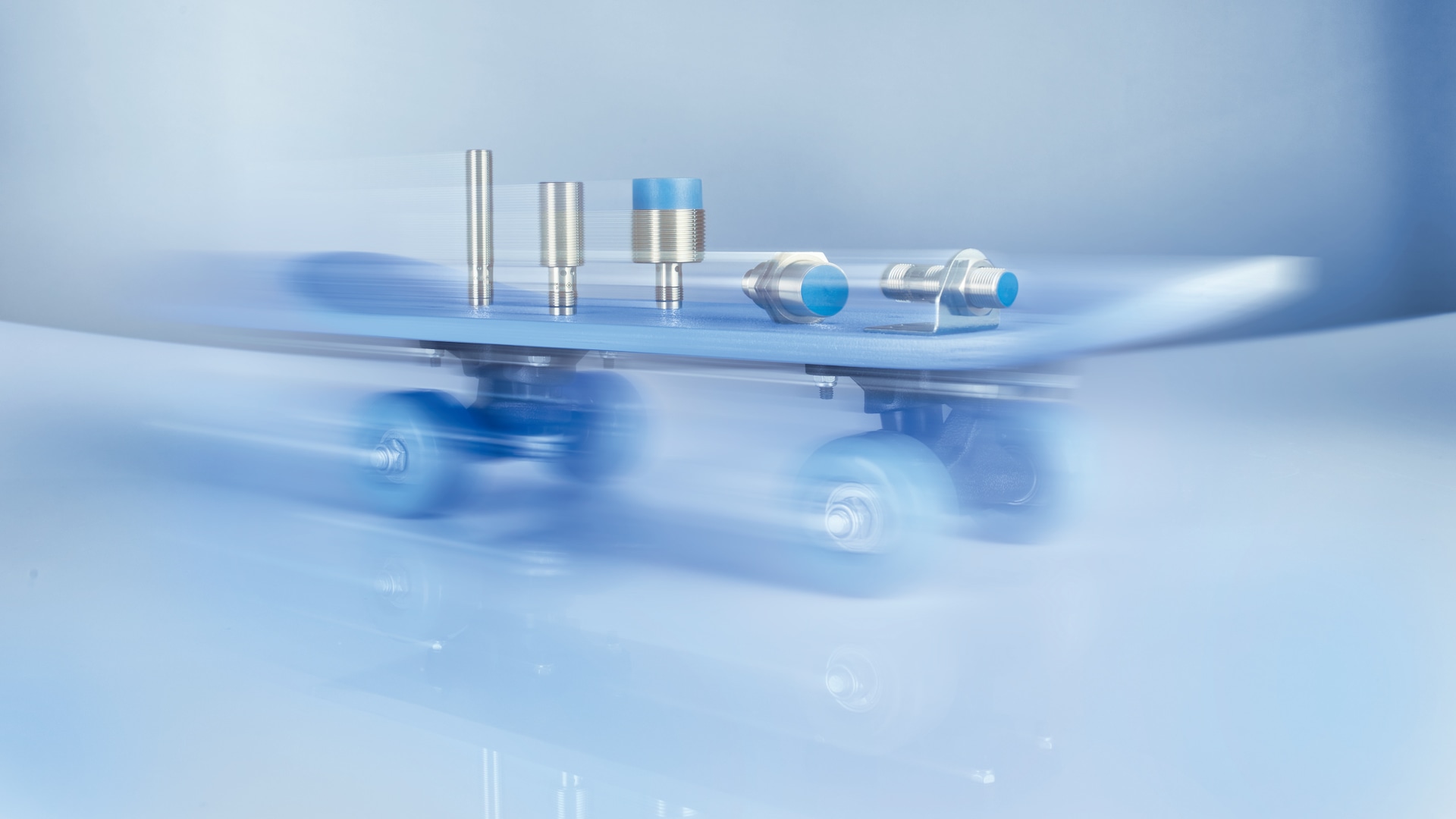

IMG Inductive standard sensors for economical use in outdoor applications

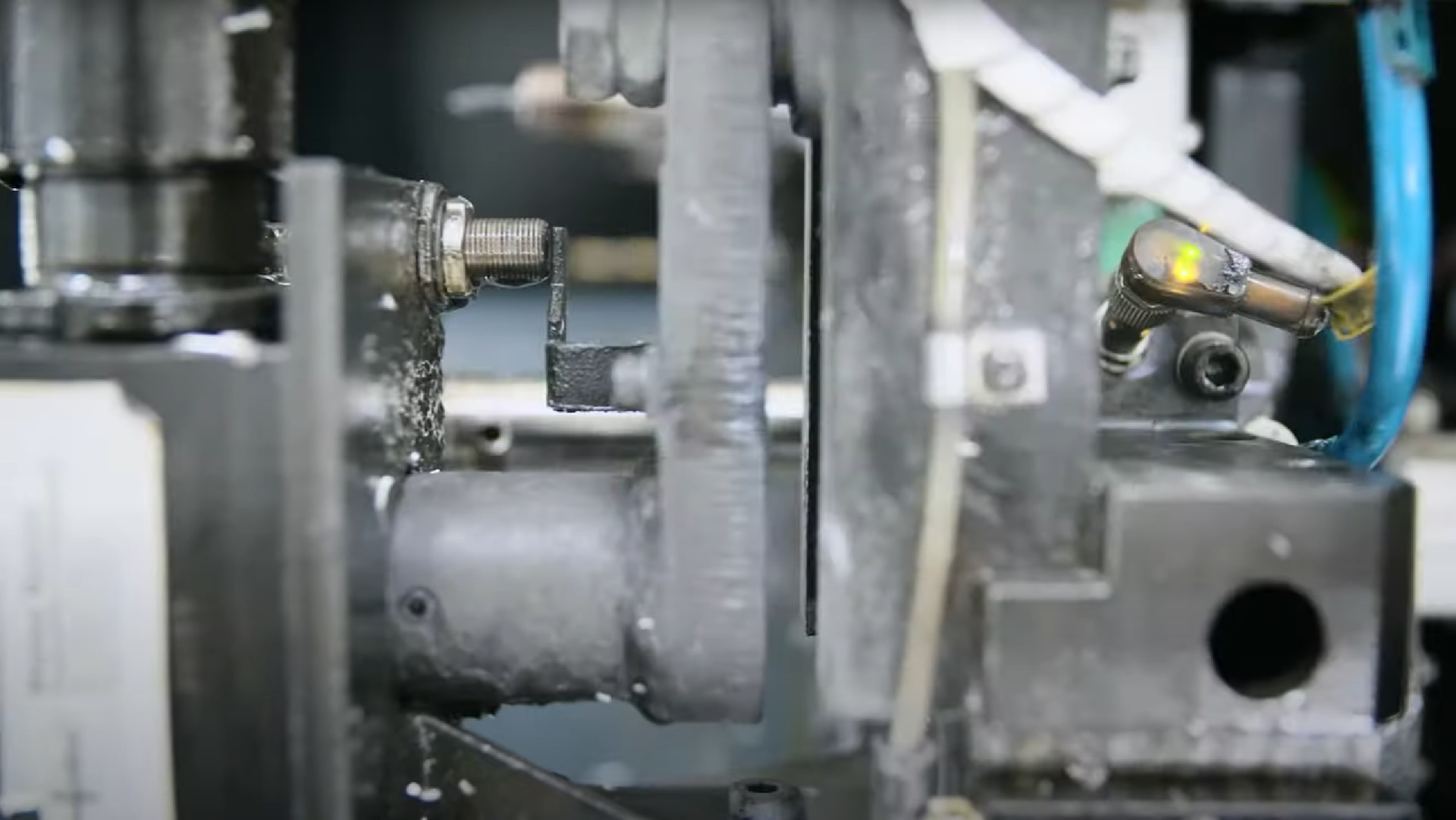

The IMG inductive proximity sensor precisely detects metallic objects even in harsh usage environments. In price-sensitive mobile applications and automation solutions, it is suitable as a switch for end position determination of speed measurement. Using the IMG, fault-free processes can be ensured even with high temperature fluctuations. The fully-encapsulated sensor is impervious to mechanical shocks as well as vibrations and with its IP69K rating is protected against water as well as oils, coolants and all kinds of contamination. This makes the IMG an economical solution for challenging outdoor uses and machine construction. Thanks to plug and play, the sensor can also be commissioned quickly.

IMG AT A GLANCE

Benefits

- High availability and long service life thanks to rugged design according to enclosure ratings IP68 and IP69K

- For harsh environments and demanding weather conditions with high humidity, extreme temperatures or constant vibrations

- Reliable detection thanks to SICK ASIC technology

- Optimized price/performance ratio due to incorporating only the essentials but with high-quality components and features

- Fast commissioning without prior parameterization

- Fault-free signal transmission thanks to high electromagnetic compatibility

Features

- Types: M12, M18, M30

- Extended sensing ranges: 4 to 20 mm

- Electrical configuration: DC, 3-wire

- Enclosure rating: IP67, IP68, IP69K

- Temperature range: –40 to +85 °C

- Nickel-plated brass housing, plastic sensing face (LCP)

- Resistant to oil and cooling lubricants; suitable for use outdoors

Advantages

High precision in a harsh work environment

Reliability that pays off: The IMG is the rugged solution for price-sensitive applications.

Durability for many fields of application

Versatility: Thanks to its ruggedness, the IMG can be used in a variety of environments and applications.

Technical details

Features

| Housing | Metric |

| Housing | Short-body |

| Thread size | M18 x 1 |

| Diameter | Ø 18 mm |

| Sensing range Sn | 8 mm |

| Safe sensing range Sa | 6.48 mm |

| Installation type | Flush |

| Switching frequency | 1,000 Hz |

| Connection type | Male connector M12, 4-pin |

| Switching output | NPN |

| Switching output detail | NPN |

| Output function | NC |

| Electrical wiring | DC 3-wire |

| Enclosure rating | IP67 1)

IP68 1) IP69K 2) |

| Special features | Resistant against coolant lubricants, Temperature resistance |

| Special applications | Zones with coolants and lubricants, Mobile machines, Difficult application conditions |

| Items supplied | Mounting nut, brass, nickel-plated (2x) |

1) According to EN 60529.

2) According to ISO 20653:2013-03.

Mechanics/electronics

| Supply voltage | 10 V DC … 30 V DC | ||||

| Ripple | ≤ 10 % | ||||

| Voltage drop | ≤ 2 V 1) | ||||

| Time delay before availability | ≤ 100 ms | ||||

| Hysteresis | 3 % … 20 % | ||||

| Reproducibility | ≤ 2 % 2)

3) |

||||

| Temperature drift (of Sr) | ± 10 % | ||||

| EMC | According to EN 60947-5-2 | ||||

| Environmental test | Quick temperature change EN 60068-2-14, Na: TA = –25 °C, TB = 75 °C, t1 = 40 min, t2 = < 10 s, 300 cycles | ||||

| Corrosion test | Salt spray test EN 60068-2-52: severity 5, 4 cycles | ||||

| Continuous current Ia | ≤ 200 mA | ||||

| No load current | ≤ 10 mA | ||||

| Short-circuit protection | ✔ | ||||

| Power-up pulse protection | ✔ | ||||

| Shock and vibration resistance | Vibration resistance acc. to EN 60068-2-6 Fc: 60 g peak (10 Hz … 2,000 Hz)

Long-term shock resistance acc. to EN 60068-2-27 Ea: 100 g 2 ms sinusoidal; 500 shocks in each direction of the 3 coordinate axes Broadband noise acc. to EN 60068-2-64: 15 g rms (5 Hz … 2,000 Hz) / 8 hours in each direction of the 3 coordinate axes |

||||

|

|||||

| Ambient operating temperature | –40 °C … +85 °C | ||||

| Housing material | Nickel-plated brass | ||||

| Sensing face material | Plastic, LCP | ||||

| Housing length | 49.4 mm | ||||

| Thread length | 31.4 mm | ||||

| Tightening torque, max. | ≤ 30 Nm | ||||

| Protection class | III | ||||

| UL File No. | E181493 | ||||

1) At Ia max.

2) Supply voltage UB and constant ambient temperature Ta.

3) Of Sr.

Safety-related parameters

| MTTFD | 1,820 years |

| DCavg | 0 % |

| TM (mission time) | 20 years |

Reduction factors

| Note | The values are reference values which may vary |

| St37 steel (Fe) | 1 |

| Stainless steel (V2A, 304) | Approx. 0.72 |

| Aluminum (Al) | Approx. 0.37 |

| Copper (Cu) | Approx. 0.29 |

| Brass (Br) | Approx. 0.39 |

Data Sheet: PDF

More Inductive Proximity Sensor Models from SICK

In addition to the SICK IMG18-08BNOZC0K, we offer a wide range of other SICK inductive proximity sensor models to meet various industrial automation needs. These sensors are designed for reliable object detection without physical contact, with options suitable for different applications in manufacturing, logistics, packaging, and more. Here’s a list of additional models from the SICK IMG series inductive proximity sensor line:

IMG30-20NNSZC0K – 1135632,

IMG12-04BPSZC0S – 1094334,

IMG18-12NPOZC0K – 1135593,

IMG30-15BNOZU2K – 1135651,

IMG12-08NPSZU2S – 1135517,

IMG30-20NNOZU2K – 1135657,

IMG12-08NNSZC0S – 1135528,

IMG12-08NNOZC0K – 1135549,

IMG30-15BNOZC0S – 1135653,

IMG30-15BPSZU2K – 1135612,

IMG30-15BPSZC0S – 1135615,

IMG30-15BPOZU2S – 1135642,

IMG12-04BPSZC0K – 1094333,

IMG18-12NNOZU2K – 1135606,

IMG18-08BNOZC0K – 1135599,

IMG30-20NNOZC0K – 1135656,

IMG18-12NPSZU2K – 1135570,

IMG12-08NPSZU2K – 1135514,

IMG18-12NNOZC0K – 1135605,

IMG30-20NPOZU2K – 1135645,

IMG18-12NPOZU2S – 1135597,

IMG30-20NPSZC0S – 1135621,

IMG12-04BPOZC0K – 1135531,

IMG18-08BPOZC0K – 1135587,

IMG12-08NPOZU2K – 1135538,

IMG12-04BPSZU2K – 1135510,

IMG12-04BNOZU2S – 1135547,

IMG30-15BPOZC0K – 1135638,

IMG30-20NPSZU2K – 1135619,

IMG18-12NNOZU2S – 1135609,

IMG12-04BNOZC0S – 1135546,

IMG12-08NPOZC0K – 1135537,

IMG30-20NNOZC0S – 1135659,

IMG30-20NPOZC0S – 1135647,

IMG18-08BPSZC0K – 1135563,

IMG18-12NNOZC0S – 1135608,

IMG30-15BPOZC0S – 1135641,

IMG18-12NPSZC0S – 1135572,

IMG30-20NNOZU2S – 1135660,

IMG30-15BNOZU2S – 1135654,

IMG12-08NPSZC0S – 1135516,

IMG18-08BPSZU2S – 1135567,

IMG30-20NPSZC0K – 1135618,

IMG12-04BPOZC0S – 1135534,

IMG18-12NPOZU2K – 1135594,

IMG30-20NPSZU2S – 1135622,

IMG30-15BPOZU2K – 1135639,

IMG18-12NNSZC0K – 1135581,

IMG30-15BPSZC0K – 1135611,

IMG12-04BPSZU2S – 1108130,

IMG18-12NPSZC0K – 1135569,

IMG18-08BPOZC0S – 1135590,

IMG18-08BNSZU2K – 1135576,

IMG30-20NNSZU2K – 1135633,

IMG30-20NNSZC0S – 1135635,

IMG18-12NNSZC0S – 1135584,

IMG12-04BNSZU2S – 1135523,

IMG12-08NPOZC0S – 1135540,

IMG18-08BNSZU2S – 1135579,

IMG12-04BPOZU2S – 1135535,

IMG18-12NPOZC0S – 1135596,

IMG18-08BPSZC0S – 1135566,

IMG12-08NPOZU2S – 1135541,

IMG12-04BNOZC0K – 1135543,

IMG12-04BPOZU2K – 1135532,

IMG12-08NNSZU2S – 1135529,

IMG12-04BNSZC0K – 1135519,

IMG18-12NNSZU2K – 1135582,

IMG12-08NNSZU2K – 1135526,

IMG12-08NPSZC0K – 1135513,

IMG12-04BNSZU2K – 1135520,

IMG12-08NNOZU2K – 1135550,

IMG18-12NPSZU2S – 1135573,

IMG12-08NNOZU2S – 1135553,

IMG18-08BNSZC0K – 1135575,

IMG12-04BNSZC0S – 1135522,

IMG30-15BNSZU2K – 1135625,

IMG30-20NPOZC0K – 1135644,

IMG12-04BNOZU2K – 1135544,

IMG18-08BNSZC0S – 1135578,

IMG18-08BNOZU2K – 1135600,

IMG30-15BNOZC0K – 1135650,

IMG30-15BNSZC0S – 1135629,

IMG12-08NNOZC0S – 1135552,

IMG30-15BNSZU2S – 1135630,

IMG12-08NNSZC0K – 1135525,

IMG18-08BPSZU2K – 1135564,

IMG18-08BNOZU2S – 1135603,

IMG18-08BPOZU2S – 1135591,

IMG30-20NNSZU2S – 1135636,

IMG30-15BPSZU2S – 1135616,

IMG18-08BNOZC0S – 1135602,

IMG18-08BPOZU2K – 1135588,

IMG30-20NPOZU2S – 1135648,

IMG30-15BNSZC0K – 1135624,

IMG18-12NNSZU2S – 1135585