LEUZE Fork Photoelectric Sensor GS 754B/D24-98-S12

Mouth width: 98 mm.

Analog output: Analog output, Current.

Description

Fork Photoelectric Sensor GS 754B/D24-98-S12

Fork Photoelectric Sensor GS 754B/D24-98-S12

General information

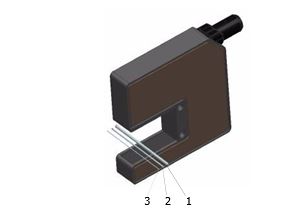

The central part of the unit is an optical sensor that generates a horizontal band of light .

The band of light illuminates a CCD line array camera. This CCD array produces an output signal that depends on the number of illuminated pixels.

The system has a permanent calibration and guarantees maximum precision and stability at all times.

Every sensor features two interfaces.

Fork Photoelectric Sensor GS 754B/D24-98-S12

TECHNICAL DATA:-

Optical data:-

| GS 754B | ||

| Output modes 1 … 5 | Output mode 7 (default) | |

| Measurement range | 25mm | 25mm |

| Mouth width | 27mm/98mm | 27mm/98mm |

| Mouth depth | 42mm | 42mm |

| Resolution | £ 0.1mm over the entire measurement range | ³ 0.014mm per measurement level |

| Smallest object | ³ 0.5mm | ³ 0.5mm |

| Light source | infrared LED | infrared LED |

| Wavelength | 850nm | 850nm |

LED indicators:-

| LED | Meaning |

| green, continuous light | Ready |

| green, flashing | Interference |

Diameter determination:-

Depending on which interface is used, data for up to three objects can be output. Data for more than one object can only be transmitted via the serial interface.

The analog value is always based on the edge or diameter information.

“Diameter determination application example”

ASCII representation via RS 232 (P and M12 interfaces:-

| Parameter | ASCII output data via S1 and S2 | |

| Q,q | Single-object detection | Middle pos. : xxx Diameter: xxx |

| W,w | Detection of two objects | Middle pos. : xxx Diameter: xxx Middle pos. : xxx Diameter: xxx |

| E,e | Detection of three objects | Middle pos. : xxx Diameter: xxx Middle pos. : xxx Diameter: xxx Middle pos. : xxx Diameter: xxx |

ASCII representation, output modes 1 … 5.

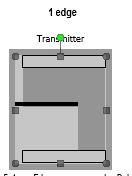

Edge measurement and height verification:-

With this measurement, the sensor expects only one edge within the measurement field.

If more or fewer edges are detected by the system, depending on the configuration , this leads to an error message.

Various configurations are possible with this measurement . The following only applies to devices with an analog interface:-

- Linear edge measurement over the entire measuring range (s. point 8).

- Teach-in edge measurement with 5V-output at teaching point.

Width measurement:-

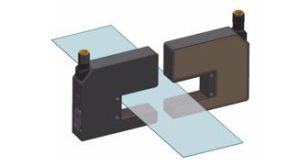

To measure the width of strip material, two GS 754B CCD forked photoelectric sensors can be used mutually opposed from one another.

Each forked photoelectric sensor relays an edge position which can be extrapolated to the total width when the distance of the sensors vis-à-vis one another is known in the control.

In conjunction with this, time synchronization of the measurement data is ensured via PIN 2 as a trigger input.

If the control generates a LOW -> HIGH signal change at the trigger inputs, then both forked photoelectric sensors simultaneously each start an output cycle.