LANNY E1B40AFEL MLS Control Valve Series E

Fields of application for Lanny valves

- Mechanical Engineering

- Packaging and food industry

- Medical and Analytical Instrumentation and Systems

- Automotive industry

Description

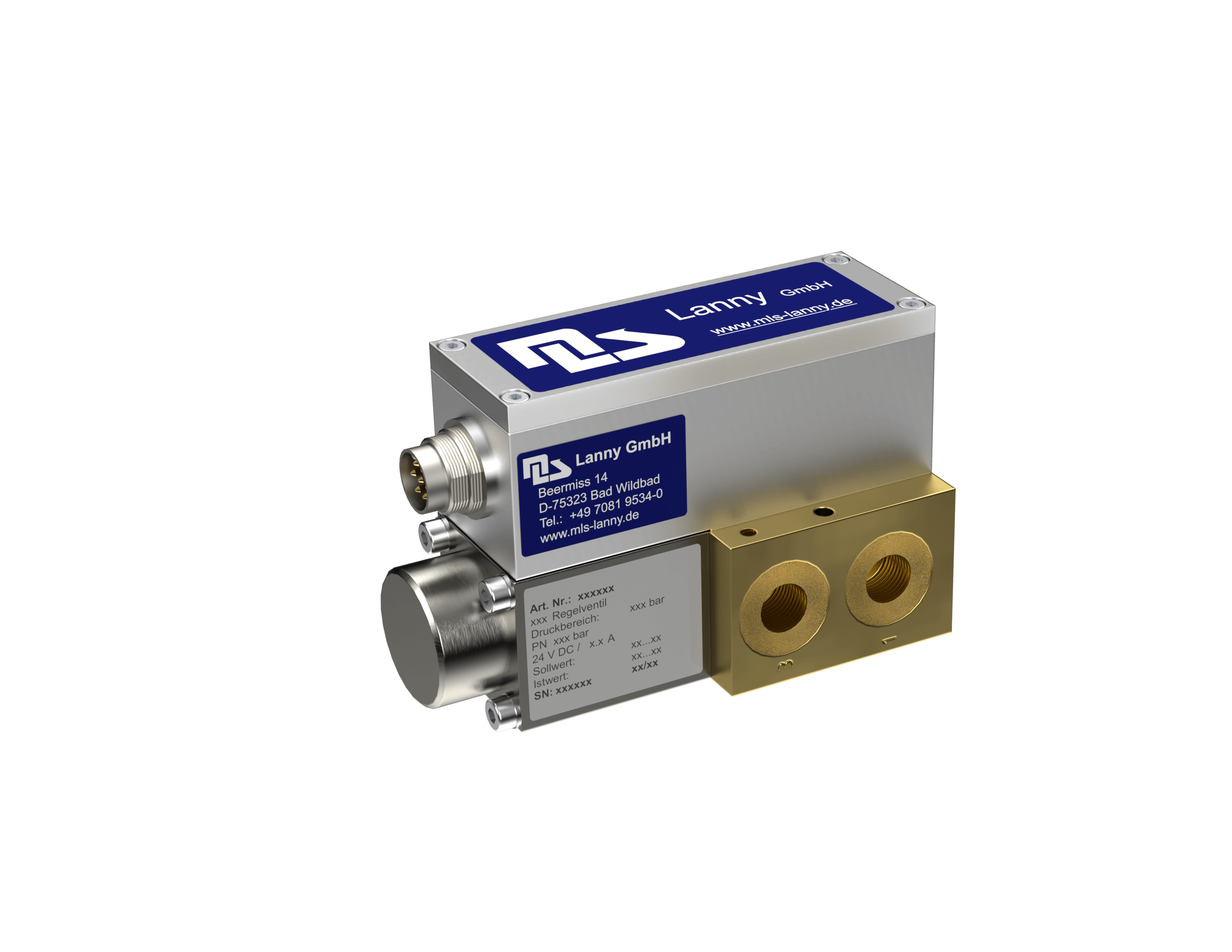

LANNY E1B40AFEL MLS Control Valve Series E

LANNY E1B40AFEL

MLS Control valves Series E are particularly suitable for controlling compressed air and other gases for a wide range of industrial applications. With 1/4 inch connections and a flow rate of 800 l/min, this series offers perfect conditions for use in the laser industry, e.g. in laser focusing.

Typical application:

Can be used as a pilot valve.

| TechniCAL DATA | |

| Connections | G1/4 |

| Pressure range | Input max. 60 bar Output max. 50 bar Vacuum |

| Flow rate @ PIN 8 / Pout 7 bar(a) | Seat 8 mm, 800 l/min Seat 6 mm, 400 l/min |

| Valve type | 3/2 way valve |

| Media exposed parts | Brass, stainless steel, nickel-plated steel |

| Operating media | Compressed air or other gases |

| Sealings | Depending on operating media |

| Input filter | 150 μm |

| Power supply voltage | 24 V DC |

| Communication system | Profibus, Profinet, Ethercat, IO-Link, analog, digital |

| Weight | ca. 1.5 kg |

For fluid technology Engineered control valve solutions

Control valves, such as our pressure control valves and flow control valves, are crucial components in industrial processes that precisely control the flow of liquids and gases. They ensure optimum operating conditions and make a significant contribution to efficiency and safety.

Main functions: Our mostly solenoid operated proportional valves provide precise control in pneumatics and hydraulics. They are robust and durable to ensure reliable performance even under extreme conditions.

Advantages:

-

High precision: Fully integrated electrical control enables maximum precision for various applications.

-

Versatility: Suitable for pneumatic and hydraulic systems in numerous applications.

-

Durability: Manufactured from high quality materials for a long service life.

-

Reliability: Ensures consistent performance, even in demanding environments.

Applications: Control valves are used in all industries, e.g. chemical, oil and gas, water treatment and many other areas where precise control is essential. Lanny valves are also suitable for high-pressure applications. you can find more information on the areas of application.

| SERIES | CONNECTIONS | PRESSURE RANGE | FLOW RATE PIN 8 / Pout 7 bar(a) |

APPLICATION / SPECIAL FEATURES | ||

|

D | G1/8 | Input max. 16 bar Output max. 16 bar Vacuum |

280 I/min | Top performance with minimum mounting space. Also available for oxygen applications. Can be used as a pilot valve. |

|

|

E Standard- application |

G1/4 | Input max. 50 bar Output max. 50 bar Vacuum |

800 I/min | For versatile use. Mechanical engineering, ultrasonic welding, test benches. Can be used as a pilot valve. |

|

|

E Laser |

G 1/4 | Inpput max. 40 bar Oxygen max. 20 bar Output max. 40 bar |

800 I/min | Optimized for laser cutting applications. Large control range. Highly precise even at low pressure levels. Very stable even at high pressure levels. |

|

|

E EFL |

G 1/4 Flange |

Input max. 50 bar Output max. 50 bar Vacuum |

800 I/min | For versatile use. Test benches. Pilot valve, e.g. for dome pressure reducers. |

|

|

EHPm EHPmFL |

G 1/4 Flange |

Input max. 300 bar Output max. 250 bar |

400 I/min | For versatile use. Test stands/test systems. |

|

|

EHP EHPFL |

G1/4 | Input max. 700 bar Output max. 700 bar |

110 I/min | For versatile use. Test stands/test systems. Gas injection molding |

|

|

F Laser |

G3/8 | Input max. 40 bar Oxygen max. 20 bar Output max. 40 bar |

900 I/min | Optimized for laser cutting applications. Large control range. Highly precise even at low pressure levels. Very stable even at high pressure levels. |

|

|

F | G3/8 | Input max. 50 bar Output max. 40 bar Vacuum |

900 I/min | For versatile use. Mechanical engineering, ultrasonic welding, test benches. Can be used as a pilot valve. |

|

|

G | G1/2 | Input max. 20 bar Output max. 20 bar Vacuum |

1420 l/min | For versatile use. Packaging industry. |

|

|

GY Laser |

G1/2 | Input max. 40 bar Oxygen max. 20 bar Output max. 40 bar |

2.200 I/min | Optimized for laser cutting applications. Large control range. Highly precise even at low pressure levels. Very stable even at high pressure levels. |

|

|

GY | G1/2 | Input max. 40 bar Oxygen max. 20 bar Output max. 40 bar |

2.200 I/min | For versatile use. Packaging industry. |

|

|

GE | Flange | Input max. 12 bar Outputmax. 10 bar Vacuum |

2.700 l/min | Beverage industry, bottling plants. 2/2-way valve bidirectional. Stainless steel, CIP-capable. |

|

|

Flow control valves | G1/8 | Input 3 … 9 bar |

0 … 75 l/min | Parallel operation for gas mixing possible. Control of shielding gas during welding. Suitable for numerous gases. |

|

|

K | G1 Flange |

Input max. 50 bar Output 0 … 40 bar |

7.000 l/min | For versatile use. Stretch blow molding machines (PET packaging), plastic processing. Especially for large flow rates. |

|

|

L | G1 ¼ Flange |

Input max. 50 bar Output 0 … 10 bar / 0 … 40 bar |

11.000 l/min | For versatile use. Stretch blow molding machines (PET packaging), plastic processing. Especially for large flow rates. |

|

|

M | G1 ½ Flange |

Input max. 50 bar Output 0 … 40 bar |

17.100 l/min | For versatile use. Stretch blow molding machines (PET packaging), plastic processing. Especially for large flow rates. |

|

|

N | G2 Flange |

Input max. 50 bar Output 0 … 10 bar / 0 … 40 bar |

39.000 l/min | For versatile use. Stretch blow molding machines (PET packaging), plastic processing. Especially for large flow rates. |

Fields of application for Lanny valves

At MLS Lanny, we are shaping the technological landscape with the help of our extensive expertise in mechanical engineering, with a particular focus on laser applications. Whether in the automotive industry, mechanical engineering, the packaging and food industry or medical technology – we are represented everywhere.

Our in-depth understanding of the industry forms the basis for customized products and solutions that are specifically tailored to your requirements. From proven standardized control valves to individual solutions, we offer a wide range of products and services.

We are proud of our development, which guarantees you efficient solutions in the shortest possible time. Our innovative modular system also ensures a high degree of flexibility to meet even the most specific requirements.

At MLS Lanny, we combine technical expertise, innovative systems and a deep understanding of industry-specific requirements to create first-class solutions. This enables us to fulfill our main objective of meeting your individual needs with the best possible solution.

Your challenges are our motivation!

Mechanical Engineering

Efficient valves are essential in mechanical engineering to ensure the reliable operation of your systems. We at MLS Lanny have therefore set ourselves the task of optimizing our valves so that they ensure the most accurate supply of your process gases and guarantee you maximum safety and efficiency through very precise control. Areas of application in mechanical engineering include laser cutting and welding, controlling the contact pressure of the sonotrode in ultrasonic welding, controlling the coolant in precision grinding or controlling the contact pressure for hydraulic systems.

Packaging and food industry

The level of automation in the packaging and food industry is constantly evolving, and we are an integral part of this dynamic trend. Our products are used, for example, in the production of PET packagings using the stretch blow molding (SBM) process, where they provide the entire air supply into the machine with filtration and precise pressure control. Our products not only increase the productivity of your machines, but also improve their service life and user-friendliness.

Medical and Analytical Instrumentation and Systems

Especially in medical and analytical technology, our valves are an elementary and important component of the systems. We at MLS Lanny take this responsibility seriously and guarantee the highest precision and safety in the control of gases and liquids with the help of our valves.

Automotive industry

The automotive sector benefits from our pneumatic control and switching valves every day thanks to their wide range of applications and precise control. Our valves support the automation of your production processes and at the same time increase the efficiency of your production systems many times over. Application examples can be found, for example, in the production of tires, where our valves regulate the pressure in the vulcanization systems, or in pressure test benches.

Tags:

Lanny valve, MLS Lanny valve, Lanny on-off valve, Lanny STD valve, Lanny switching valve, Lanny PV1B40 valve, PV1B40 STD valve, PV1B40 on-off valve, D01A0Y valve, D01A03V valve, E1B20AFEL valve, Lanny E1B20AFEL, DM0051 Lanny, DM0051D01A03V, DFL1805-K2VC1 valve, E1B20AFEL, DFPROB07 valve, B1B06AF valve, RVA1 Lanny valve, B1B10AFR valve, B1B10AZ-HER valve, B1B20AMF valve, B1B40AF valve, B1B40AFBL valve, BHPB40BLZ V3 valve, B5B25ADM-V3, K2VC1B25 valve, Lanny valve Bangladesh, Lanny Bangladesh, F7DF25AM, LV840 valve, PV1840 STD valve, PVB40STD valve, PV1840/2, grooved type Lanny valve, oil-resistant Lanny valve, M8 connector valve, Lanny industrial valve, on-off control valve, compact switching valve, square type valve, high-performance Lanny valve, durable Lanny valve, standard Lanny on-off valve, precision fluid control valve, automation valve Lanny